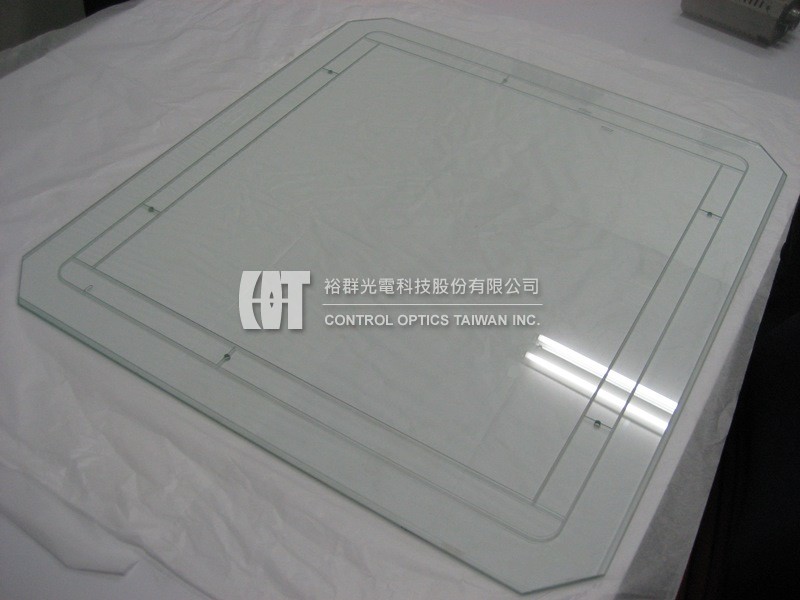

真空吸著基板

石英材質基板被廣泛應用於光學及光電產業,因為高純度、無雜質、無氣泡等級的石英基板材料,具有優異的UV波段光學穿透性能,能生產精度高的高品質石英基板,再加上具耐腐蝕、耐高溫的特性,石英基板常應用於UV波段之曝光系統元件。

石英基板製造專家-裕群專業製造石英材質真空吸著基板

裕群光電專精於高純度石英基板與真空吸著基板的設計與製造,產品廣泛應用於半導體製程、光電設備、UV曝光系統、雷射加工平台與光學元件支撐應用等。高純度石英材質真空吸著基板就選裕群光電

裕群光電採用Fused Silica熔融石英、Synthetic Quartz合成石英材質、Sapphire藍寶石、超白玻璃材質、SodaLime商用青板玻璃材質、陶瓷材質、SiC碳化矽材質(碳化硅)所製成之吸著真空石英基板,品質優良高效率,致力提供您更好的石英材質基板。石英基板/石英材質真空吸著基板的外型塑造須歷經CNC成型、光學研磨、光學拋光、貼合、金屬機構件、真空吸著管路組裝等生產過程,透過嚴謹的製造工序與過程,成就出品質優異的石英材質基板產品。

石英基板材料特性:

- 圓型產品拋光尺寸可達直徑5000mm,方型產品拋光尺寸可達3500mm x 3500mm

- 提供可見光波段產品,亦可選用光學玻璃材質製作高精度石英基板

- 石英材質基板適用於UV紫外光波段,具UV紫外光波段高穿透特性,可大幅減低UV能量耗損

- 石英材質具有低膨脹系數的特性,相較於一般玻璃更不易變型

- 高精度石英基板平行度可達秒級,平坦度可達2um(視材質、尺寸、形狀、厚度而定)

- 小尺寸石英基板吸著溝槽寬度可小至300um、溝槽深度可達200um

- 大尺寸石英基板吸著溝槽可做拋光處理

- 長方型的石英基板也可以研磨拋光

- 可使用膠合方式固定通氣流道及通氣管路