石英、陶瓷、硬脆材料、金屬件加工

產品介紹:

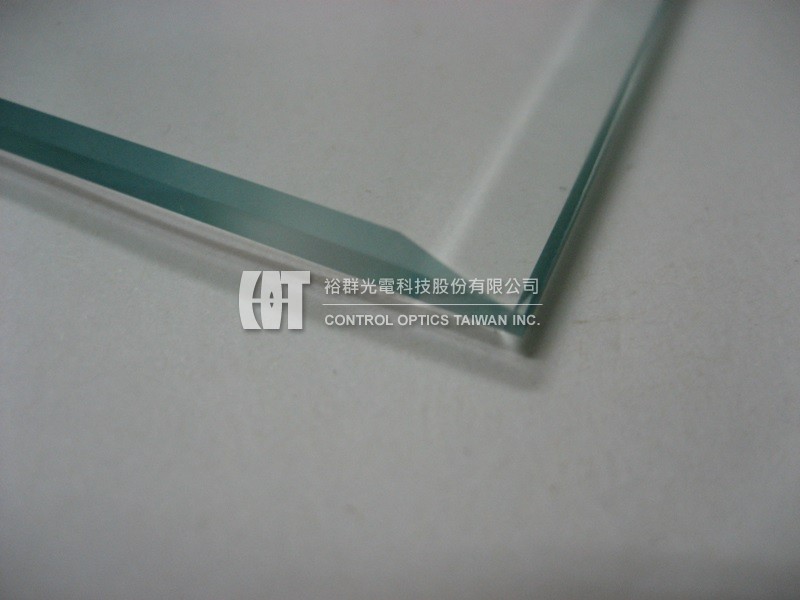

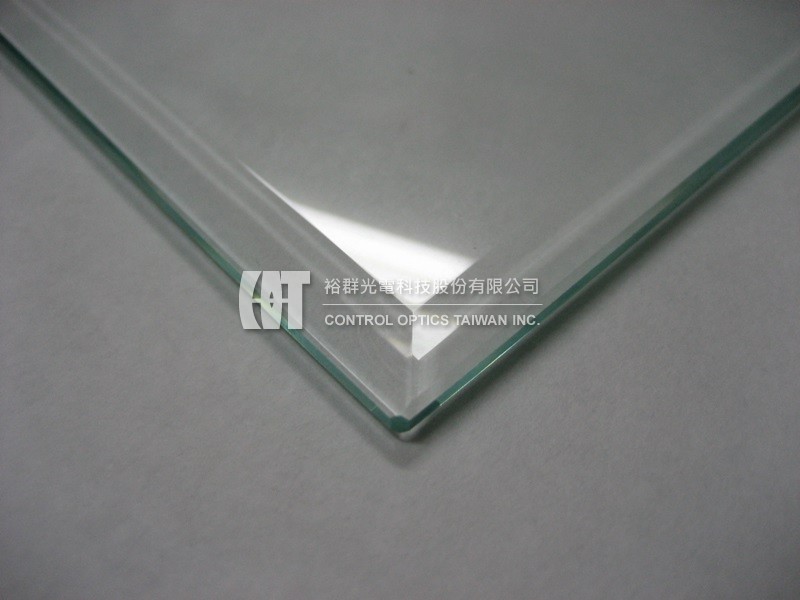

裕群光電建置CNC銑床、CNC切割機、車床、滾圓機、曲面成型機、鑽石磨輪降面機、鑽石磨輪切割機、大型光學研磨機、大型光學拋光機、UV固化貼合機、大型清洗架、真空吸著管路組裝設備、真空管路測漏幫浦等製程設備,針對光學級石英、陶瓷、硬脆材料、金屬件加工領域擁有多年經驗,專精超高平坦度、超高平行度、超高面型精度、細小粗糙度的加工提供客戶完整的技術方案。

裕群光電專精Fused Silica熔融石英、Synthetic Quartz合成石英材質、Sapphire藍寶石、SodaLime青板玻璃、陶瓷材質、SiC碳化矽 (碳化硅)、ZERODUR®零膨脹微晶玻璃、CLEARCERAM™零膨脹微晶玻璃、鋁鎳金屬、硬脆材料之切割成型、滾圓、成型、鑽孔、溝槽、微孔、噴砂、顯影蝕刻、研磨拋光加工。若您有石英、陶瓷、硬脆材料、金屬件加工需求,歡迎洽詢。

產品特色:

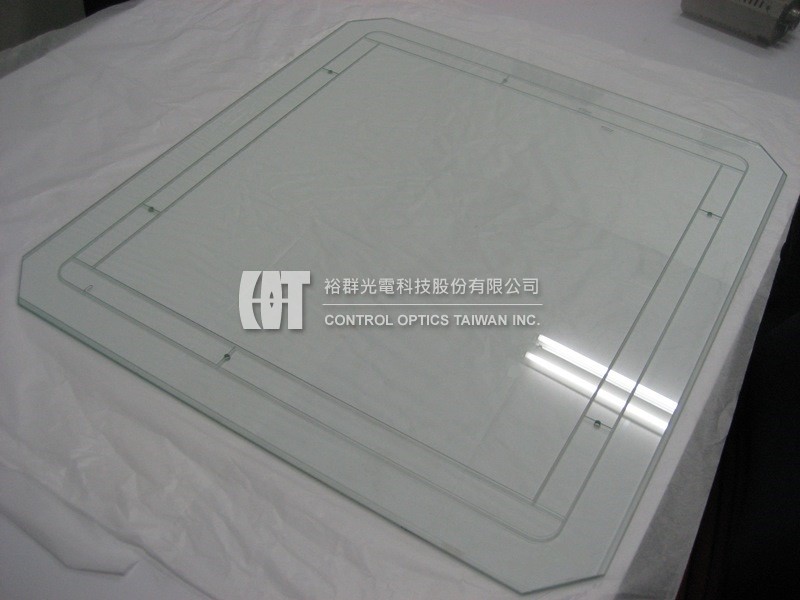

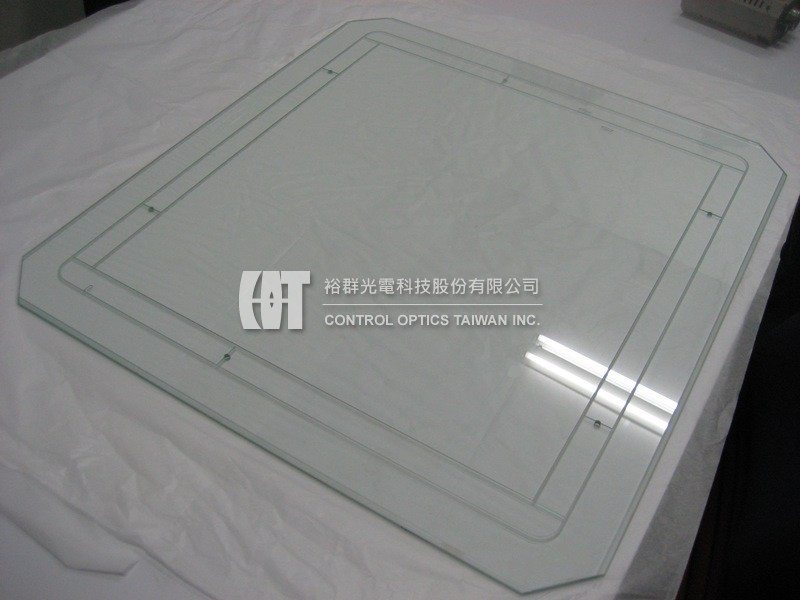

一、圓型產品拋光尺寸可達直徑5000mm,方型產品拋光尺寸可達3500mm x 3500mm

二、高精度基板平行度可達秒級,平坦度可小於2um(視材質、尺寸、形狀、厚度而定)

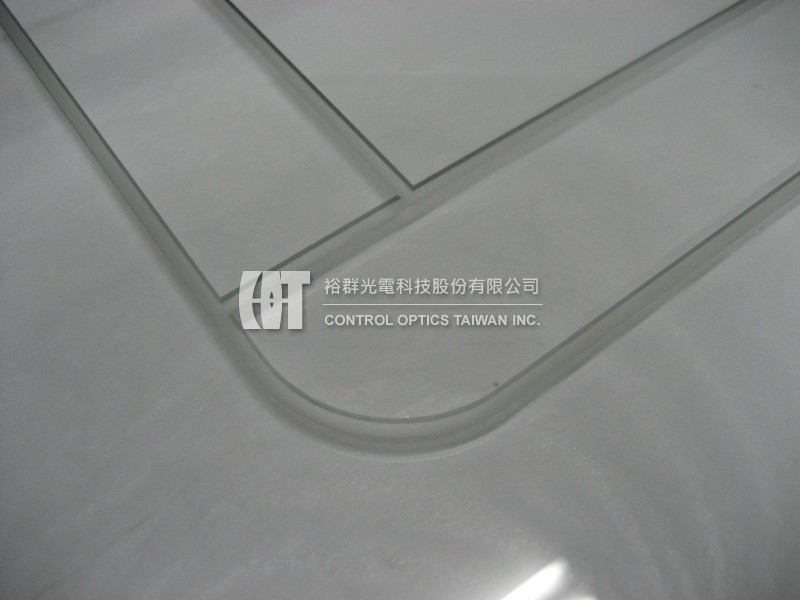

三、小尺寸基板吸著溝槽寬度可小至300um、溝槽深度可達200um

四、石英材質具有低膨脹系數的特性,相較於一般玻璃較不易變型

五、石英材質基板適用於UV紫外光波段,具UV紫外光波段高穿透特性,可大幅減低UV能量耗損

六、長方型的基板及長條型基板也可以研磨拋光,尺寸長度可達1800mm

七、可使用膠合方式固定通氣流道及通氣管路

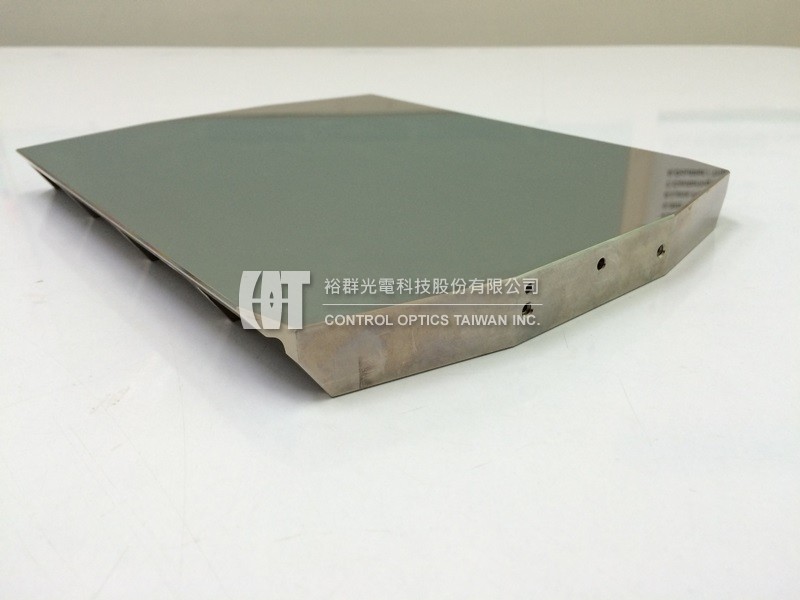

八、鋁材質基板及光學級鋁反射鏡可在表面鍍上無電解鎳,可將無電解鎳研磨拋光至光學面再鍍膜

九、金屬模仁常使用的STAVAX材質,可在表面鍍上無電解鎳,再將無電解鎳研磨拋光至光學面

十、金屬件可搭配金屬超精密加工Diamond turning process,將表面車銑加工至光學面